Forklift OPH01/E Order Picker (RATED LOAD:3000KG LIFTING HEIGHT:4500MM-6000MM) none

Product selling point:

RATED LOAD:3000KG

LIFTING HEIGHT:4500MM-6000MM

High performance and high efficiency

Lifting and deceleration function

Intelligent operation is safe and reliable

Wide field of view

It is equipped with a high-performance lithium battery as standard

The OPH01/E order picker is a specialized type of industrial truck designed for efficient order picking and retrieval tasks in warehouse and distribution center environments. Let’s explore some of the key usage occasions and applications for this order picker model:

Forklifts sale

Order pickers and forklifts are both important types of material handling equipment, but they serve distinct purposes and have different capabilities. Let’s take a closer look at the key differences between these two industrial vehicles:

Order Pickers:

– Primary Function: Order picking and retrieval

– Design: Elevated platform that raises the operator to access items on shelves

– Mobility: Compact, maneuverable design for navigating tight aisles

– Lift Capacity: Typically lower than forklifts, ranging from 1,000 to 3,000 lbs

– Lift Height: Can reach heights of 15-30 feet to access items on tall shelves

– Applications: Warehouse order fulfillment, retail replenishment, inventory management

Forklifts:

– Primary Function: Lifting, transporting, and stacking heavy loads

– Design: Lifting forks mounted on a mast, with the operator seated below

– Mobility: Larger, more powerful design for moving bulky, palletized loads

– Lift Capacity: Typically higher than order pickers, ranging from 3,000 to 15,000 lbs

– Lift Height: Capable of reaching heights of 15-30 feet, similar to order pickers

– Applications: Material handling in warehouses, manufacturing facilities, construction sites

Key Differences:

1. Operator Position: Order pickers have an elevated platform that raises the operator, while forklifts have a seated operator position below the forks.

2. Load Capacity: Forklifts generally have a higher lift capacity, making them better suited for moving heavier, palletized loads.

3. Maneuverability: Order pickers are designed for tight, narrow aisles, while forklifts are larger and better suited for open spaces.

4. Applications: Order pickers excel in order picking and retrieval tasks, while forklifts are more versatile and can handle a wider range of material handling needs.

In many warehouse and distribution operations, order pickers and forklifts work in tandem to create an efficient and comprehensive material handling system. Order pickers handle the order fulfillment and retrieval tasks, while forklifts transport the palletized loads and replenish the shelves. The combination of these two specialized pieces of equipment helps optimize storage, reduce labor costs, and improve overall productivity.

描述

The OPH01/E order picker is a specialized type of industrial truck designed for efficient order picking and retrieval tasks in warehouse and distribution center environments. Let’s explore some of the key usage occasions and applications for this order picker model:

Inventory Management:

– The OPH01/E order picker is well-suited for conducting inventory audits and cycle counts by allowing the operator to easily access and inspect stock at various shelf levels.

– Its height-adjustable platform and high lift capability enable the operator to reach items stored on upper and lower shelves, ensuring comprehensive inventory visibility.

Order Fulfillment:

– This order picker of industrial equipement is primarily used for order picking, where the operator can travel alongside the racking system, retrieve the required items, and place them directly onto a pallet or cart.

– The platform’s ability to raise and lower allows the operator to efficiently gather items from multiple levels, optimizing the order picking process.

Narrow Aisle Operations:

– The compact design and precise maneuverability of the OPH01/E make it well-suited for use in tight, narrow warehouse aisles where space is limited.

– Its ability to navigate through narrow passages and around tight corners helps maximize storage capacity and warehouse density.

Retail Replenishment:

– In retail settings, the OPH01/E order picker can be used to restock shelves and displays, allowing the operator to easily access and retrieve items from upper and lower shelves.

– This helps ensure that the sales floor is well-stocked and visually appealing to customers.

Cross-Docking and Transloading:

– The OPH01/E’s lifting capabilities and compact size make it useful for cross-docking and transloading operations, where items need to be efficiently transferred between different modes of transportation.

– The ability to access and move items at various heights facilitates the smooth flow of goods through the distribution hub.

Loading and Unloading Trucks:

– The order picker’s versatility extends to loading and unloading trucks, where the operator can use the platform to access and handle items stored on the upper levels of the trailer.

– This helps streamline the loading and unloading process, reducing labor costs and improving overall efficiency.

The OPH01/E order picker‘s combination of height adjustability, maneuverability, and precision control makes it a valuable asset in a wide range of materials handling applications, from inventory management to order fulfillment and retail replenishment, across various industrial and commercial settings.

—

ΟΡΗ 01/01Ε

Electric picker

Strong and reliable design

High cost performance

Easy maintenance

Low noise

The OPH01/01E is a compact yet flexible and efficient modern multi-function picker. With a maximum working height of 5m, it is suitable for almost all small and medium-sized indoor Spaces, whether it is storing goods or indoor maintenance. The 750mm vehicle width and 1454mm minimum vehicle height mean that it can easily enter a variety of narrow scenes (elevators, doors, etc.). Full load operation, long battery life, perfect for heavy tasks. It can be said that it is the best choice to assist operators in indoor operations.

Safety is at the heart of the OPH01/01E. Operating platform lift is smooth and smooth with no frustration. The lifting and decelerating system ensures that the platform can slowly and smoothly rise to the highest point. All models are equipped with automatic sensing doors, which will automatically close, and the vehicle cannot be used when the door is opened, ensuring the safety of the operator to the greatest extent. Both hands sense the operation handle to avoid any misoperation during the work process. The lifting structure uses high-strength aluminum alloy profiles to implement the concept of lightweight, which not only reduces the impact of body weight on endurance, but also improves the high stability. The chassis is equipped with rubber cushion around, which can reduce the impact of the vehicle while driving and ensure the safety of the driver and passenger.

All models are equipped with safety lights, buzzers, and blue day running lights on the front to provide adequate warning for the surrounding area during driving. Streamlined appearance design, beautiful and practical.

Efficiency is the goal of the OPH01/01E. The vehicle is equipped with a high-performance controller, which makes it possible to parallel the lifting process with the driving process, eliminating unnecessary operations such as a separate lifting platform, and greatly improving the working efficiency of the operator. Ac high-quality driving wheel, motor characteristics, control procedures and vehicle conditions are highly matched, each operation can respond instantaneously. Special in situ turn function, the operation space 360°, no space restrictions. Standard side lighting allows the operator to see the cargo nameplate even deep in the cargo hold.

High performance and efficiency

The unique in situ 360° rotation function, the minimum operating radius can be as low as 1300 mm, almost to meet the operation needs of all narrow areas. Intelligent high performance AC drive, OPH01/01E can accurately and quickly reach any designated location.

It has a speed of 5.5km/h

Turning radius is only

5% maximum gradient with full load

Full load lifting speed 0.2m/s

Full load descent speed 0.21m/s

1300mm

Lifting and decelerating function

Lifting and decelerating function, when the platform is lifted to close to the maximum height, the lifting speed and traveling speed will be sharply reduced (in the three areas of 0-500mm, 500-1500mm, 1500-3000) to ensure the stability and safety of the vehicle. The picking height can reach 5 meters, which is convenient for taking and placing items on the third layer of shelves.

HA

The lifting height is less than 500mm

When the lifting height is 500-1500mm

500-1500mm

0-500mm

5.5Km/h

3.2Km/h

1.4Km/h

S

Travel speed 5.5Km/h

Travel speed 3.2Km/h

Travel speed 1.4Km/h

Lifting height 1500-3000mm

Wide field of view

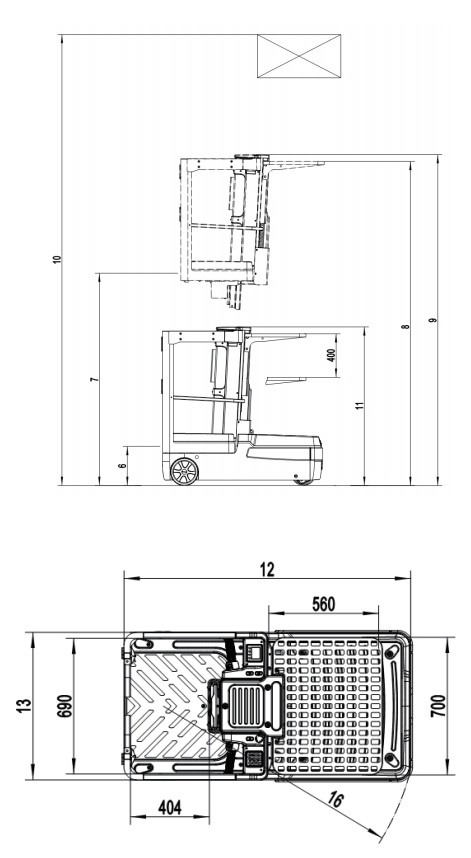

Electric retractable front panel with a minimum drop of 400 mm. Just lower the pallet height, no matter how high the cargo is, it will not obstruct the operator’s line of sight.

Straight Down.

400 mm

1500-3000mm

==

High performance lithium battery is standard

Fast charge Charge anytime, anywhere

The unique fast charge characteristics of lithium batteries can meet the work needs of multiple shifts. Compared with traditional lead-acid batteries, lithium battery vehicles do not need to change the battery during different shifts, and do not need backup batteries and charging areas. Lithium battery vehicles can be quickly charged in the interval of operation to extend the working time, there is no memory function, will not affect the life. Due to the environmental protection characteristics of lithium battery, the charger does not need to be placed in a special charging area, and the flexibility is higher.

Environmentally friendly and cost-effective

Lithium batteries are more environmentally friendly, cost-effective, free of acid evaporation, odor and pollution while charging, and maintenance-free. Zero carbon dioxide emissions,

And work relatively quietly. Therefore, lithium battery solutions are ideal for operational applications with environmental impact concerns, such as the food industry,

Chemical and pharmaceutical industries.

Thanks to the fast charge of lithium, only one set of batteries is needed per vehicle, regardless of the number of work shifts. (Lithium-ion batteries last three times longer than lead-acid batteries.) Because of their maintenance-free nature, lithium-ion batteries are more cost-effective and lower cost than lead-acid batteries.

Can-bus vehicles are equipped with high-performance controllers and CAN-BUS technology, which CAN accurately check the status of the vehicle and make fault diagnosis.

Safe, efficient and maintenance-free

The power lithium battery system is composed of: high safety and high specific energy lithium iron phosphate cell, intelligent battery management system (BMS), the communication network between the vehicle gauge level and the vehicle controller, the body, the charger and the remote management platform, real-time detection of the state of the lithium battery, the running state of the vehicle and the charging state of the charger, to protect the safety and reliability of the lithium battery to the greatest extent.

Battery energy distribution unit (BDU) and other components; Built by intelligent battery management system (BMS) : power lithium battery

Intelligent operation is safe and reliable

Hd LCD instrument panel, intuitive provide including safety tips, speed, time, power, fault code and other necessary information. No longer confused when driving.

A combination lock with a swipe card ensures uniqueness while simplifying the authentication process, especially if more than one person can operate the vehicle.

Custom left and right multi-function handle to replace the complex panel work, response is fast and accurate, lifting, walking, steering can be synchronized.

The whole model is equipped with automatic closing induction door, induction door in the open state, no

Method of using the vehicle.

The whole vehicle is equipped with buzzers, warning lights, reverse lights and blue day lights to avoid pedestrians being hit because they do not have enough warning. Side lights and optional night lights, no matter how dim the ambient light, also provide enough brightness for the operator to pick up/place the cargo.

Aluminum profile lifting structure provides smooth lifting process and stable lifting center of gravity.

Light weight can also ensure its high stability.

==

Forklifts sale|china wholesale material handling OPH01/E Order Picker Sale Buy Online Industrial Equipment

Reviews

There are no reviews yet.